Full Time Professor

Bioengineering and Chemical Engineering Department

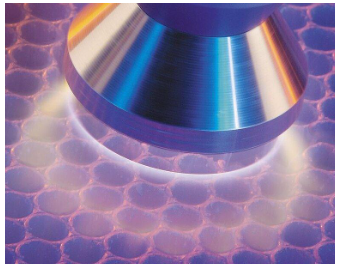

Plasma also known as the fourth state of matter can be produced artificially and used in various applications, such as material cleaning and surface pretreatment. The plasma is highly reactive and has a high electrical conductivity which allows it to act on solids such as plastic, glass or metal by modifying the properties of its surfaces.

On the other hand, the industrial sector is in the continuous search for new friendly technologies that allow them to save energy and reduce CO2 emissions. In this sense, the use of plasma is a good alternative to other surface pretreatment methods in which they use volatile organic solvents that harm health and the environment.

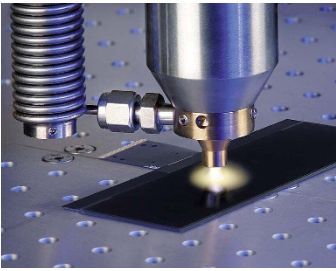

Plasmatreat GmbH, a world leader in the development and manufacture of atmospheric plasma systems, has developed technologies where it uses outdoor plasma for dry surface treatment, Thus, it is no longer necessary to perform pretreatments with chemical primers thus reducing emissions of volatile organic compounds (VOCs) during production. It also avoids the production of CO2 that is generated when flame treatment is applied, such as surface pretreatment to improve adhesion, since it does not use propane gas or methane that generate emissions to the environment. In addition, the application of plasma is carried out by rotating nozzles that operate with a minimum consumption of electricity and compressed air.

Another advantage of using PlasmaPlus technology is that it can be incorporated into new processes, since the application of nanocoatings can create additional functionalized surfaces with defined properties and can serve as a protective layer that gives additional adhesion to the material. Some applications: in UV-based printing inks, because activating a plasma surface can achieve optimal adhesion by avoiding other energy-intensive processes such as ink drying; or in plastics production, where the use of low-cost polypropylene (PP) allows reducing energy consumption in addition to the material’s own costs since it is used to replace acrylonitrile-butadiene-styrene (ABS).

Source: https://www.plasmatreat.com

Openair-Plasma technology can be used in automated and continuous manufacturing processes in industries such as textiles, electronics, automotive, packaging, among others.

“Resource savings, energy savings and cleaning: these properties make plasma technology a contemporary alternative in many industrial processes,” says Dr. Alexander Knospe, Director of Innovations at Plasmatreat GmbH.

Source: https://www.plasmatreat.com

Revista Tecnología del Plástico.com. Edition 1 Vol. 38 February – March 2023. p.48-50.