Full Time Professor

Bioegineering and Chemical Engineering Department

In my teaching experience in the Bioengineering department at UTEC I have had the opportunity to meet talented students who came to study this career with dreams of growing up as people and as professionals. Several of them found in the bioengineering the possibility to overcome challenges, solve problems, and think big when demonstrating their knowledge and skills acquired during their time at this institution.

One of the most important academic moments for any university student is the time to demonstrate their talents when developing a thesis project as the epilogue of their university studies. And at that moment I have supervised (or co-supervised) several talented students who, when creating and developing a research project in bioengineering, elaborate ambitious proposals that soon become projects for the solution of problems in biomedicine and biotechnology. Moreover, the ambition of these students leads them to propose long-term projects, where their respective final theses are just the first step in the ascent to the practical solution and not simply a degree requirement, but will continue developing into applied proposals for the actual solution of the problems under consideration.

In my role as a teacher of the Bioengineering Final Project course (where our students are doing their thesis), I would like to share some of the ambitious and revolutionary projects that our students have carried out in the course that is now ending in 2023.

Some of our students have decided to propose solutions to address the problem of the lack of organs and tissues for implantation in patients who have lost them and are waiting for organ and tissue donations to live.

Students Yue Yang and Rafaella Camere have focused their efforts and talent to develop biomimetic corneas from extrusion-based 3D bioprinting.

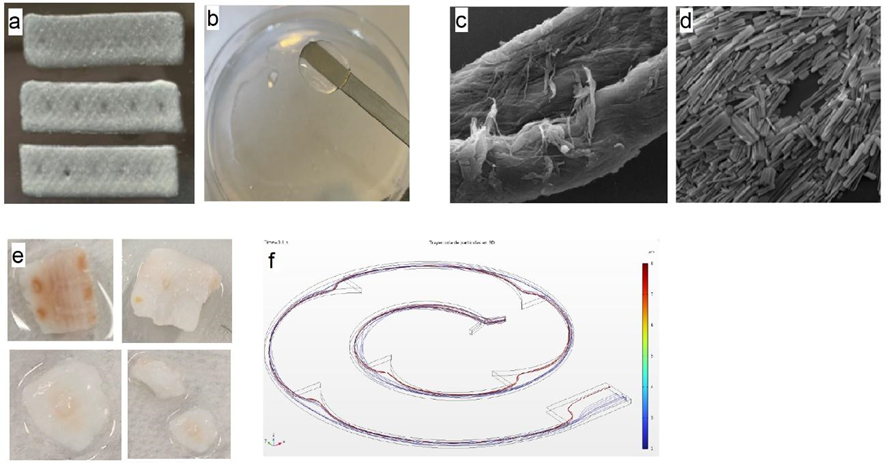

Inspired by the native microstructure of corneas, Yue Yang has focused her work on studying the effects of various filling patterns as well as the composition of the hydrogel (printed material) on the mechanical properties of the final construct, finding that a biomimetic cornea printed as a flat disc with triangular patterns and using an alginate-gelatin hydrogel cross-linked with copper sultatate offers optimal mechanical properties although still below those reported in the literature (Figure 1 a) [1].

Rafaella Camere focused her research on testing different ink compositions for bioprinting, varying the concentrations of the materials used (sodium alginate and gelatin B) and the crosslinking agent (calcium lactate), evaluating the physical, biochemical and mechanical properties of the most promising compositions. Her research identified a wide range of effects in terms of stability, appearance and bioprintability with such variations. She identified that decreasing gelatin and increasing alginate favors the transparency of the construct, but at the cost of reducing its mechanical strength (Figure 1 b). At the same time, increasing the concentrations of the materials increases the stability of the printed model but at the cost of increasing the extrusion pressure, which should be monitored if the printed material is to include cells. Finally, she demonstrated that variations in the chemical compositions of the inks from crosslinking have an influence on the stability and mechanical response of the material, where 10% of crosslinking agent generates an elastic modulus similar to that of bovine corneas [2].

César Argüelles and Pedro Toledo have developed a biopolymer composed of recombinant proteins representative of collagen and elastin, essential components that favor cell adhesion and activity in scaffolds with the intention of serving as a base for the culture of living tissues. Although their standardized process to obtain the biopolymer was optimized and efficient, it generated quantities of the biopolymer below those reported in the literature. Nevertheless, they managed to morphologically characterize this compound, evidencing its potential for use in tissue culture scaffolds (Figure 1 c and d) [3].

Regarding the generation of new scaffolds for bone tissue formation, Nicole Regrat and Rafael Carbajal have investigated the potential of corn pith as a scaffold for the formation of this tissue given its microarchitecture and mechanical capacity. Their process included decellularization and mechanical characterization of the decellularized construct, finding that this process affects mechanical strength, but with the expectation of recovering this property by the mineralization provided by osteoblasts in a future cell culture (Figure 1 e) [4].

Richard calderón, from his study in computational microfluidics, has designed a chip for the efficient separation of erythrocytes that in turn are microencapsulated into uniform 200 µm droplets to increase the quality and shelf life of blood stored in blood banks. This device has obtained its optimized version after studying the effect of the radius of curvature and the contraction-expansion cycles along the 3D trajectory of the blood inside the chip, finding that, by increasing that radius and setting four to five contraction-expansion cycles, the separation and microencapsulation efficiency reaches 74% (Figure 1 f) [5].

I close this article by discussing the work of three bioengineering thesis students who analyzed the performance of biomaterials for both substance release and capture.

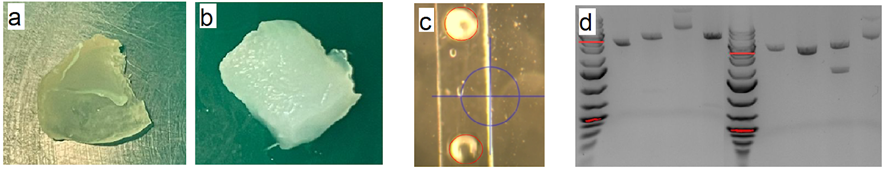

Regarding biomaterials for the controlled release of substances, Daniella Rivero analyzed the kinetic behavior of the swelling of a Phytagel hydrogel with polyvinyl alcohol under the stimulus of the pH factor as a biodegradable and mechanically resistant alternative for the controlled release of drugs (Figure 2 a and b). For this study, the pH’s present in the different segments of the human digestive system were taken as a reference. It was found that the best swelling is obtained at an acid pH factor of 5, that its highest degradation rate is in an alkaline environment with a pH factor of 8, and that its drug release is non-linear. These characteristics led to the conclusion that an optimal target point for its use is the stomach [6].

In this same line, Alexandra Valdez developed a method to have controlled release of glyphosate using microcapsules created in a microfluidic system through ionic sintering, evaluating manufacturing parameters such as the concentrations of alginate and copper sultafo (encapsulating materials) and flow rates inside the device to evaluate the size and structure of the capsules, as well as the release rate of the herbicide. This research found that the microcapsules formed have diameters around 300 µm, the size of which depends on the flow rate of glyphosate (Figure 2 c). After 10 hours in an aqueous medium, the microcapsules had released 7% of the encapsulated substance [7].

Finally, applying synthetic biology concepts, Nadia Chamana developed a continuous evolution system (something like modifying genomic structures to cause high-speed natural evolution) to trap carbon dioxide from the environment using algal photosynthesis as the operating principle. Such a system allowed the creation of genomes that, intercalated in existing natural chains, have the potential to capture more carbon, developing a concept for the elimination of the greenhouse effect (Figure 2 d) [8].

These projects presented are an example of the research around which the identity and image of our bioengineers is built. Hey world, here you have the bioengineers of UTEC.

References

[1] Y. Yang, “Optimization of the design process of tissue-engineered corneal scaffold through pneumatic extrusion-based 3d bioprinting”, Bachelor thesis, Departamento de Bioingeniería e Ingeniería Química, UTEC, Lima, Peru, dec 2023.

[2] R. Camere, “Diseño de hidrogeles a base de alginato de sodio y gelatina tipo B para bioimpresión 3d de tejido corneal con visión a trasplante”, Bachelor thesis, Departamento de Bioingeniería e Ingeniería Química, UTEC, Lima, Peru, dec 2023.

[3] C. Argúelles and P. Toledo, “Diseño, síntesis y caracterización de un nuevo biopolímero a base de la combinación de colágeno y elastina recombinantes para la formación de andamios con aplicación en la regeneración de tejidos”, Bachelor thesis, Departamento de Bioingeniería e Ingeniería Química, UTEC, Lima, Peru, dec 2023.

[4] R. Carbajal and N. Regrat, “Desarrollo de un andamio a partir de la coronta de Zea mays, L. (choclo) para obtener un modelo óseo”, Bachelor thesis, Departamento de Bioingeniería e Ingeniería Química, UTEC, Lima, Peru, dec 2023.

[5] R. Calderón, “Desarrollo de un lab-on-a-chip para la separación y microencapsulamiento de eritrocitos en alginato con el fin de mitigar las lesiones de almacenamiento en bancos de sangre”, Bachelor thesis, Departamento de Bioingeniería e Ingeniería Química, UTEC, Lima, Peru, dec 2023.

[6] D. Rivero, “Analysis of Swelling behavior and characteristics of a phytagel (PHY) and Polyvinyl alcohol (PVA) based hydrogel for its future application as a Drug delivery system”, Bachelor thesis, Departamento de Bioingeniería e Ingeniería Química, UTEC, Lima, Peru, dec 2023.

[7] A. Valdez, “Desarrollo de un sistema de liberación controlada basado en microcápsulas de Cu-alginato cargadas con pesticida glifosato a partir de un dispositivo microfluídico con geometría de enfoque de flujo”, Bachelor thesis, Departamento de Bioingeniería e Ingeniería Química, UTEC, Lima, Peru, dec 2023.

[8] N. Chamana, “Maximization of the CO2 fixation in chlamydomonas reinhardtii using an in vivo continuous directed evolution system”, Bachelor thesis, Departamento de Bioingeniería e Ingeniería Química, UTEC, Lima, Peru, dec 2023.